The Heart of Innovation: How IPCON Engineering Filaments Power

At EagleSight Dynamics, we transform the artistry of natural flight into the next generation of Bionic Flapping-Wing Drones. At the core of this leap is our proprietary, compact high-torque power module. Turning this intricate design from a digital model into a reliable, production-ready core was made possible by a partner who defines engineering boundaries with material science: IPCON.

Precision Material Strategy: Where Every Component Meets Its Perfect Match

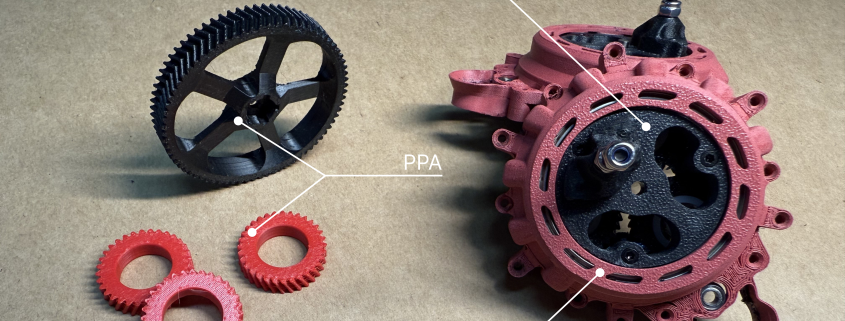

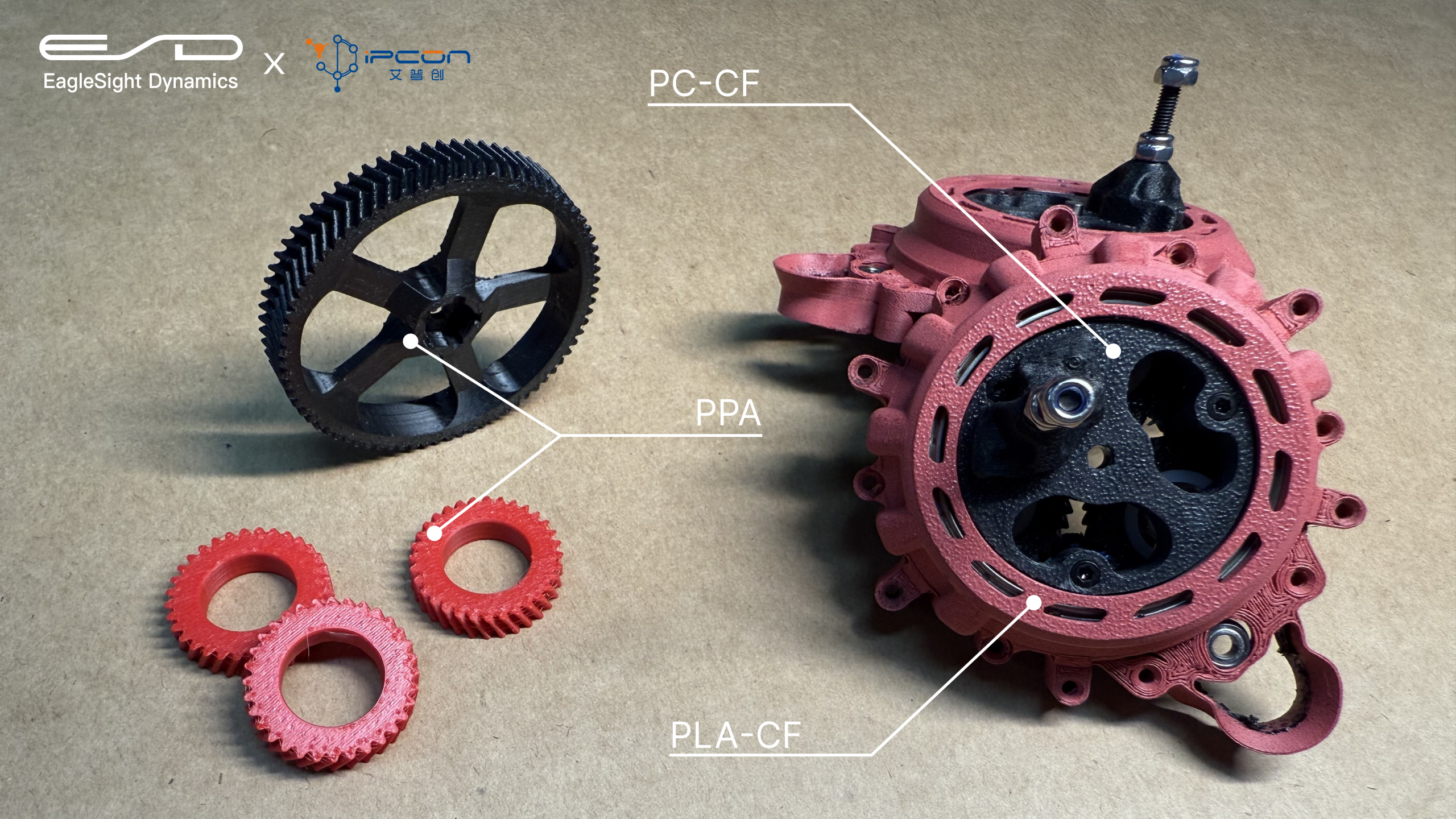

Our philosophy is precise alignment—material properties must directly serve component function. The images below reveal more than parts; they show the material logic that drives our design.

Strategic material selection in action. Each component is matched with a specific IPCON filament engineered for its unique performance requirements.

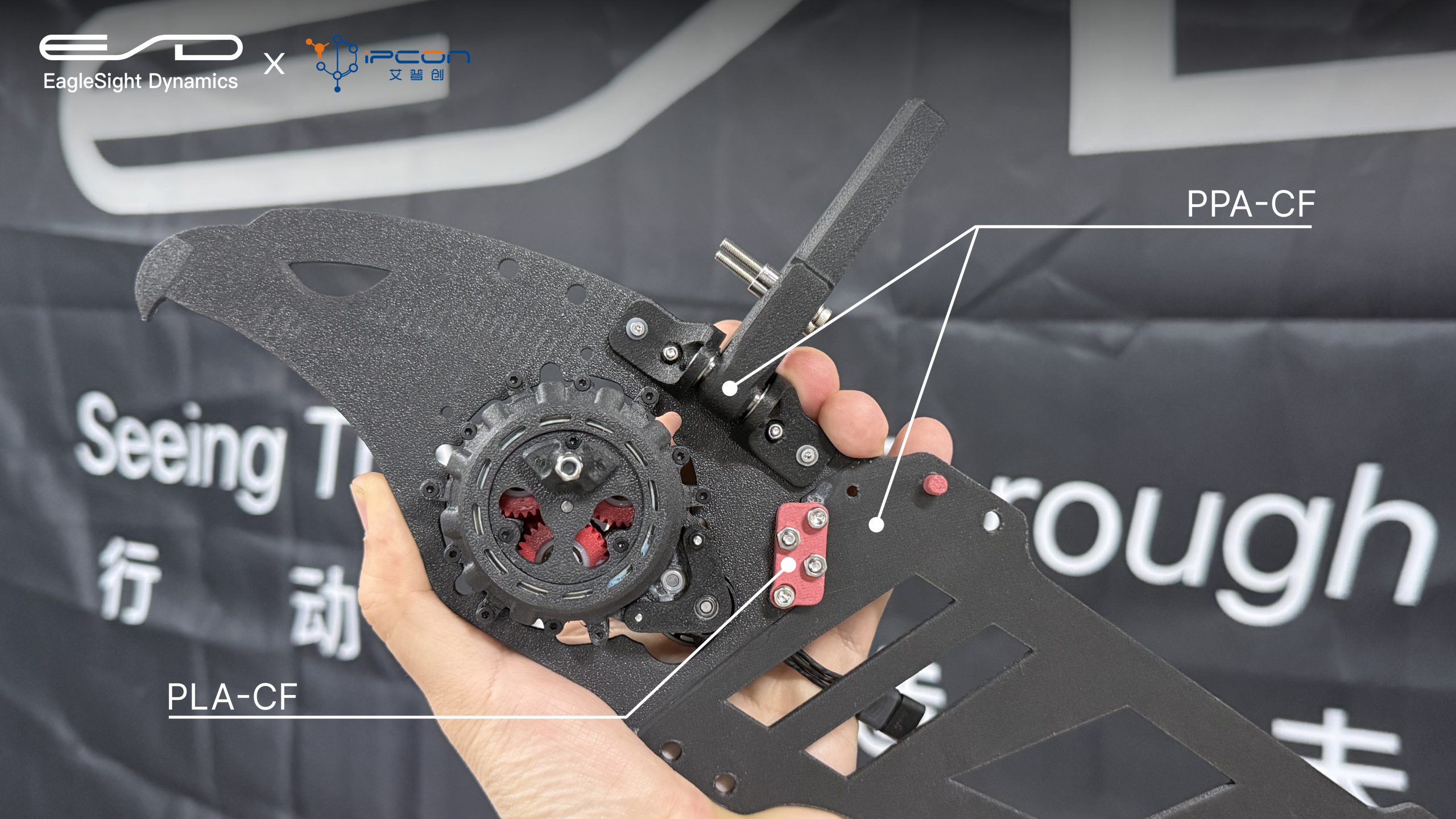

The final assembly—where material properties converge into a lightweight, robust, and precision-crafted “flight engine.”

As illustrated, IPCON’s advanced material portfolio provides targeted solutions:

- IPCON PC-CF forms the module’s “skeleton”—the central housing. Its exceptional stiffness, strength, and thermal stability ensure the power core remains unwavering under high stress.

- IPCON PLA-CF brings to life the iconic red helical gear and related components. It delivers significantly enhanced rigidity alongside superb printability and surface finish, enabling complex geometries that marry reliability with visual distinction.

- IPCON PPA is chosen for critical precision gear systems. Engineered for minimal weight, outstanding wear resistance, and long-term dimensional stability, it ensures lasting precision and low-friction performance in high-speed transmission.

- IPCON PPA-CF is applied to key load-bearing frame structures. This carbon-fiber-reinforced PPA composite significantly increases structural stiffness and resistance to deformation while maintaining lightweight advantages, providing a solid foundational support for the entire power module.

From Prototype to Flight: Validation, Integration, and Beyond

Material choices are validated through rigorous testing. The journey from individual parts to a fully integrated system is where IPCON materials help us push performance limits.

This video captures how IPCON filaments transform from reel to reliable flight force.

The result is a highly integrated, lightweight, and resilient core. Strategically using IPCON PLA-CF for the main wing structure and IPCON PPA for the drive arm achieves the optimal balance of durability, minimal mass, and precise movement essential for true biomimetic flight.

Conclusion: Partnering with IPCON to Land Innovation Reliably

The EagleSight Dynamics Bionic Drone is born from the synergy of biomimetic vision and advanced material science. IPCON Engineering Filaments, with their reliable performance, excellent printability, and comprehensive portfolio, have been the key enabler and fundamental pillar in transitioning our proprietary power module from an innovative concept to a producible, high-performance reality.

IPCON 3D Printing Engineering Filaments — Where Advanced Materials Meet Pioneering Design, Enabling the Production of High-Performance Innovation.